|

There are two equally important aspects to sail design:

aerodynamic shape and engineering. Aerodynamic shape refers to

the curved foil that the sail will present when it is flying

under certain conditions. Engineering refers to the various

fabrics and fibers that will be used in building this foil and

the precise manner in which they will be put together. In fact,

these two aspects of sail design go hand in hand since a perfect

shape is useless if it distorts when a load comes on the sail.

Similarly, an over-engineered sail is equally useless if its

shape is not conducive to good performance. This balance between

shape and engineering is a delicate one, and the process starts

with a careful analysis of the various loads that the sail will

undergo when it is being used. Once the sail engineer knows

precisely what loads the sail will encounter he can build it

accordingly using just enough fiber and fabric to handle the

anticipated loads without any unwanted stretch or extra weight.

| ď . . . a perfect shape is

useless if it distorts when a load comes on the sail.Ē |

This load analysis has two parts to it. The first is called

finite element analysis in which a sophisticated computer program

simulates the sail flying in various wind strengths and angles,

and then graphically represents the different loads in the sail.

The second involves calculating the exact strength and stretch

resistance of each individual fiber and the finished fabric that

is to be used in the sail. As discussed in chapters 2 and 3, a

good fabric engineer will know both the tensile strength and

yield strength of the various fibers, and will be able to provide

the sail designer with this information so that it can be

factored into the engineering process. The designer can then take

full advantage of the strength and stretch attributes of the

sailcloth and then incorporate them into his design. The goal is

to keep the sail as light as possible, but still strong enough to

be usable throughout its designed wind range without changing

shape. Panel layouts and corner engineering are also an important

part of this process, although before we look at this area in

more detail, we need to take another look at the critical subject

of load analysis.

Finite Element Analysis

Finite element analysis programs came about because of the

complex nature of some of the engineering problems faced not only

by sail engineers, but by engineers in general. For example, itís

fairly easy to calculate how much a steel beam will deflect when

it is suspended between two points. Itís also fairly easy to

calculate the loads a sail will be subjected to under specific

set of conditions. The problem however is that the conditions

never remain the same for more than an instant. Wind strength,

waves, heel angle, air density and a myriad of other factors come

into play. Therefore, in order for the engineer to calculate how

the fibers and fabric will respond to the different conditions,

he needs to break the entire problem down into small, solvable

problems, and then feed this information into a finite element

analysis program that will be able to solve the larger complex

problems that result. The small, solvable problems can be

expressed as mathematical algorithms that can then be

interpolated into the engineering requirements for the more

complex problems. Only by knowing the answer to the most basic of

equations can the larger engineering problems be solved.

The sail designer starts with some basic information. He has

the geometry of the sail, the designed shape and the anticipated

wind range for the sail. All this information can be entered into

the finite element analysis program, which will then represent

the sail graphically on a computer screen. Once he has all this

information in place he can begin to manipulate the conditions.

He can increase the wind strength and see what result it has on

the fabric. He can move the sheet lead position and see how the

load paths in the sail change. He can also alter the wind angle

and ease the sheet to watch how the loads in the sail will travel

along different catenaries. Since a sail is an object that can be

infinitely manipulated, and the wind is an infinitely variable

element, another job of a sail engineer is to decide which

parameters to engineer the sail around. For example, if he is

designing a headsail for an Americaís Cup boat that he knows will

only be used on an inshore course for sailing as close to the

wind as possible, he would not bother too much about wider wind

angles. Instead, he would have the computer program simulate the

sail being used within its designed wind range sailing hard on

the wind and see what loads the sail encounters. If, on the other

hand, he is designing a headsail to be used on an Open 60 sailing

in the Southern Ocean he would know that the sail would never be

used in a hard-on-the-wind situation. Rather, the sail would be

used reaching and running. Therefore, engineering the sail for

dead upwind conditions would not make any sense. The same applies

to designing a sail for a cruising boat or a smaller one-design

boat like a Soling or a Flying Scott. The amount of analysis for

these sails will not be as much because the uses are less

complex, and the time spent doing the analysis adds to the cost

of the sail. But some kind of analysis is still important to

creating the best possible all-around sail.

|

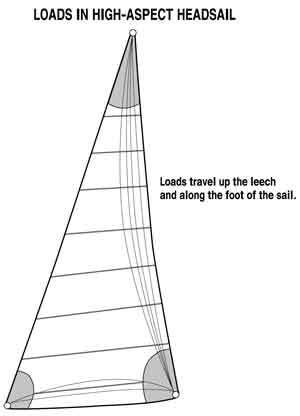

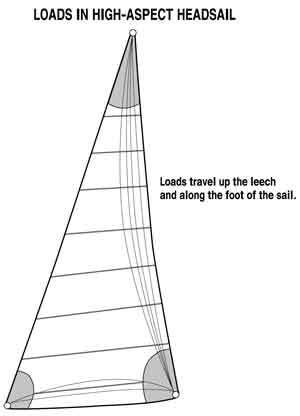

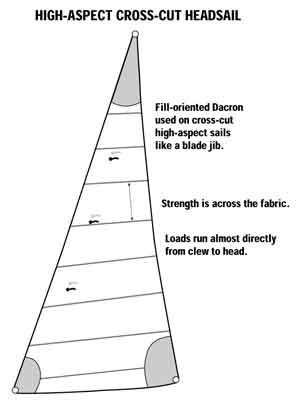

| Figure 4.1 When sailing

on the wind, a high-aspect sail like a blade jib will have

the bulk of the load travel almost directly up the leech of

the sail with less stress along the foot. |

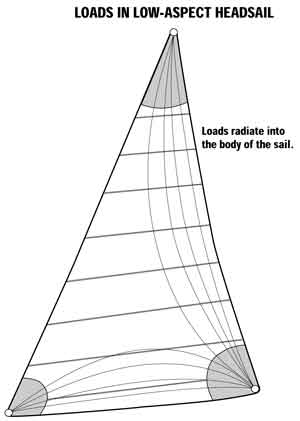

|

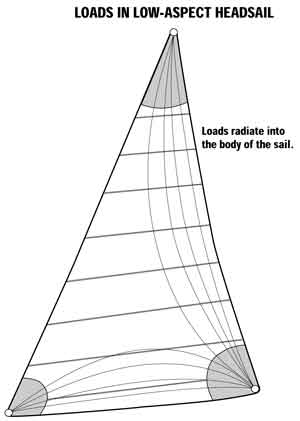

| Figure 4.2 A low-aspect

sail will have the loads travel more toward the center of the

sail rather than concentrated along the leech. It will also

experience greater loads along its foot than the high-aspect

sail. |

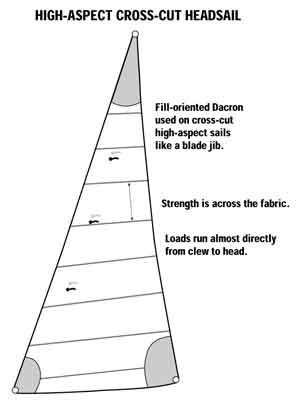

Note that the loads in a sail are also affected by the

geometry of a rig, and in particular the aspect ratio or

height-to-width ratio of the sail. For example, when sailing on

the wind, a high-aspect sail like a blade jib (Figure 4.1) will

have the bulk of the load travel almost directly up the leech of

the sail with less stress along the foot. A low-aspect sail like

a No. 1 genoa, on the other hand, will have the loads travel more

toward the center of the sail rather than concentrated along the

leech. It will also experience greater loads along its foot than

the high-aspect sail (Figure 4.2) By knowing where the loads fall

and combining this information with the strength and stretch

resistance of the individual yarns, the sail designer can begin

to develop an overall picture of an optimal panel configuration.

As you will see in future chapters the art of aligning yarns

along specific load catenaries has become a sophisticated

process, far more complicated than in the early days when there

were only a few ways to configure a panel layout. As noted in

Chapter 3 many different styles of fabric are available, and a

number of different construction techniques are also available.

Fortunately, itís not rocket science, and understanding even a

little about how and why sails are built in a particular manner

will go a long way toward helping you make the appropriate

decisions the next time you are in the market for a new sail.

Mitre- and Cross-cut Sails

Before we look at some of the latest sail designs,

however, itís once again important to look to the past. As was

the case with sail fabrics and yarns, if we understand how we got

to where we are today, we will have some idea of where we might

be going. Sail engineering is all about making good use of raw

materials, both raw fibers and sailcloth.

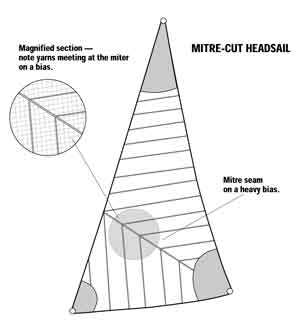

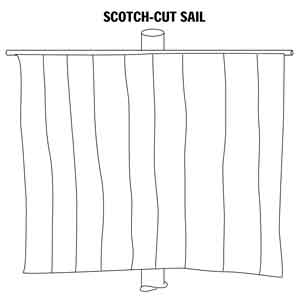

|

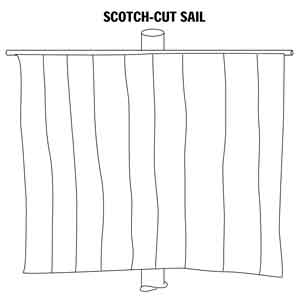

| Figure 4.3 Back in the

days of square-riggers and trading schooners all sails were

made with their panels laid parallel to the leech of the

sail in what was referred to as a Scotch-cut pattern. |

|

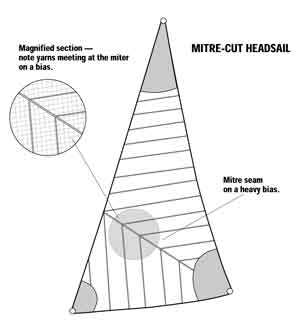

| Figure 4.4 The panels meet

in the body of the sail with adjoining panels cut at an angle

to both warp and fill yarns on what was called a heavy bias. |

Back in the days of square-riggers and trading schooners all

sails were made much the same way, i.e., with their panels laid

parallel to the leech of the sail in what was referred to as a

Scotch-cut pattern. This was true for both square sails and

triangular headsails, despite the face that they were subjected

to markedly different forces. (Figure 4.3) Then in the middle of

last century a company by the name of Ratsey and Lapthorn

Sailmakers, based in Cowes on Englandís Isle of Wight, realized

that fill yarns had less stretch than their warp counterparts,

and that this fact could be used to some advantage in terms of

sail shape. Specifically, the company discovered that by rotating

the fabric 90 degrees, it was suddenly able to achieve a moderate

amount of leech control, something that had until that point

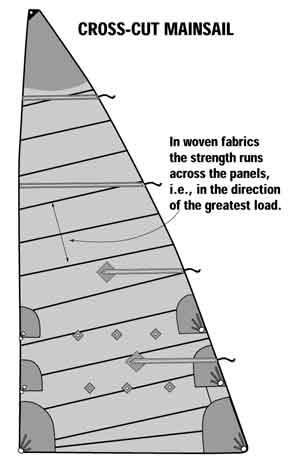

eluded sailmakers. For mainsails, where two out of three edges

are supported by rigid spars, they ran the fabric all the way

across the sail from the leech to the luff in what came to be

called a cross-cut pattern. For the headsails, which were only

supported along the luff by a headstay, they ran the panels

perpendicular to the leech, and perpendicular to the foot as well

so that both parts of the sail would benefit from the

stretch-resistant fill yarns. (Figure 4.4) The panels met in the

body of the sail with adjoining panels cut at an angle to both

the warp and fill yarns on what was called a heavy bias.

Fortunately, the middle of most sails is a low-load area so this

bias didnít result in too much distortion, although it could be

very difficult to get the sail to look good when there was so

much opportunity for stretch. In the old days, when sailmaking

was more art than science, sailmakers were often judged by how

well they could sight and cut the mitre line.

|

| Cross-cut Dacron sails

are the most common sails seen on weekends as small

cruising boats head out for a sail. |

|

| Figure 4.5 As

sailmakers gained some say in the way fabrics were woven,

they were able to get fill-oriented and balanced fabrics made

that could be used to build increasingly efficient cross-cut

sails, both headsails and mainsails. |

|

| Figure 4.6 Choose a

fill-oriented fabric for a No. 3 blade jib where the loads

run right up the leech of the sail. |

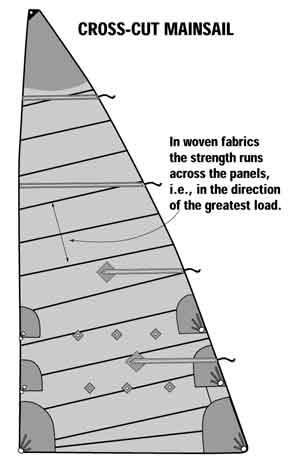

As designs developed and sailmakers gained some say in the way

fabrics were woven, they were able to get fill-oriented and

balanced fabrics made that, depending on the aspect ratio of the

sail, could be used to build increasingly efficient cross-cut

sails, both headsails and mainsails. (Figure 4.5) For example, as

Figure 4.2 shows, a low-aspect sail like a No. 1 genoa of the

kind used on an old IOR racer has the loads fairly evenly

distributed throughout the sail. Therefore, if you had to choose

a single fabric it would likely be a balanced one. If, on the

other hand, you were choosing fabric for a No. 3 blade jib where

the loads run right up the leech of the sail, you would

definitely choose a fill-oriented fabric. (Figure 4.6) As fabrics

became more sophisticated and sailmakers gained a better

understanding of their craft, sail designs improved, and the

demands for better sails increased as well. The quest for light

sails that did not stretch when they came under load remained a

top priority for sail engineers.

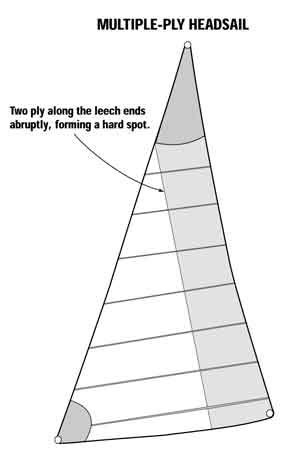

A Case for Multiple Plies

The fact that the fabric along the luff of sails was overkill was

not lost on sailmakers, but until they figured out that fabric

could be plied, or made up of multiple layers stacked on top of

one another, there was little they could do about it. Sails were

engineered for the loads on the leech and the excess fabric

strength at the front end (generally in a low load area) got a

free ride. When I worked for Hood Sails in the early 1980s we had

a lock on the maxi-boat market. Maxi boats back then were 80 feet

long, giants for their time, and the sail inventories consisted

of five or six headsails of varying sizes and weights, plus a

number of other sails like trysails and spinnakers. Some of the

boats carried 15 to 20 sails on board each time they left the

dock to go racing, which represented a tremendous bulk. It did

not make any sense to remove excess weight from the boat in the

form of spare tools and unneeded toothbrushes when the bilge was

stuffed with heavy, overbuilt sails. When they were wet, which

was much of the time, it was even more of a problem.

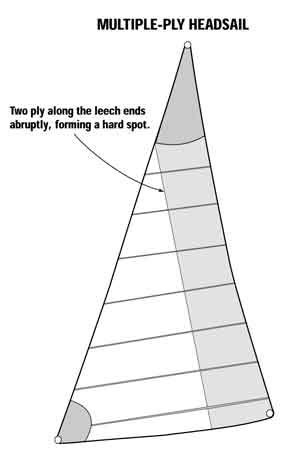

|

| Figure 4.7 The first

designs had the second ply joining the single ply along an

imaginary line that ran parallel to the leech. |

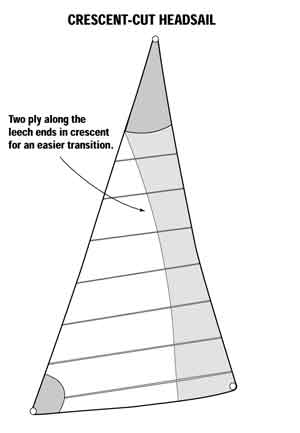

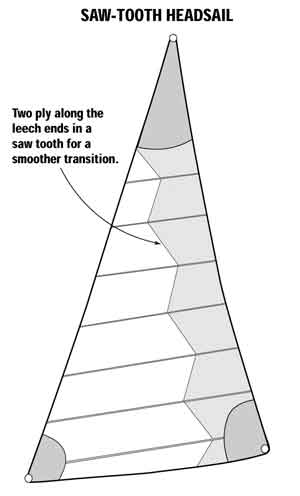

Crescent-cut and Saw-tooth Sails

Partly out of a desire to save overall weight in the

boat, and partly in an effort to engineer more efficient sails,

sailmakers started to manufacture sails that had a relatively

light base fabric, then added a second ply of woven Dacron along

the high load area, i.e. the leech. This development took place

in the early 1980s and initial forays into two-plied sails, or

sails that had heavier fabric up the leech were not a total

success. The point where the different fabric strengths came

together, for example, was an area that caused problems since a

crease or gutter quickly formed where the seam had to try to

accommodate the contrasting stretch characteristics of the

different fabrics. The first designs simply had the fabrics

joining along an imaginary line that ran parallel to the leech

(Figure 4.7). But as sailmakers began to recognise that there was

more load toward the head and clew, and less in the middle of the

sail, some started to end the second ply in a crescent shape

(Figure 4.8), while others tried their own configurations with

the result that the saw-tooth mainsail (Figure 4.9) and other

aptly named sails became part of sailmaking jargon. In each case,

the basic idea remained the same. Use heavier fabric where it was

needed and keep the rest of the sail light. Another

advantage of these two-ply sails was that they allowed the

designers to combine fabrics in a sail. For example, they could

use a balanced Dacron for the base fabric and a fill-oriented

Dacron for the second ply up the leech. This way the yarns were

being used to their fullest potential. They even tried three-ply

sails, but the added expense of building the sails did not show

commensurate gains in performance. After much analysis and trial

and error, sailmakers found which fabrics could be plied and

matched with others and that if they carried the transition point

further into the body of the sail there was less chance of a

problem occurring. It was a cumbersome process and sail engineers

knew there had to be a better way. Fortunately, it was just about

this same time that laminated fabrics began gaining a foothold in

the industry.

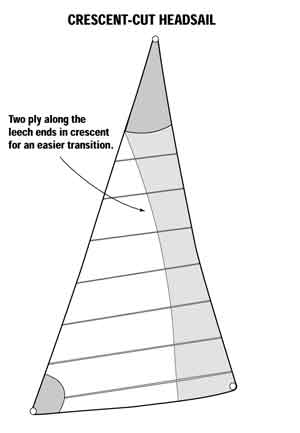

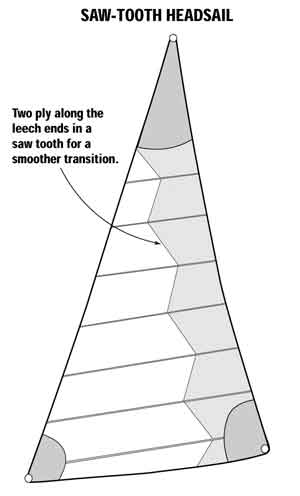

|

|

| Figure 4.8 |

Figure 4.9 |

| As sailmakers

began to recognize that there was more load toward the head

and clew, and less in the middle of the sail, some started to

end the second ply in a crescent shape (Figure 4.8), while

others tried their own configurations resulting in the

saw-tooth sail (Figure 4.9). |

A Primer of Panel Layouts will continue in the August 2004 issue

of Northern Breezes.

Brian Hancock is an expert in sails, sailmaking, and offshore

ocean racing, having made a career as a professional sailor for

almost three decades. He apprenticed at Elvstrom Sails in South

Africa before leaving the country to sail around the world. In

1981/82 he sailed as a watch captain aboard the American yacht,

Alaska Eagle in the 27,000 Whitbread Round the World race. Four

years later he returned for a second Whitbread, this time aboard

the British yacht, Drum. In 1989 he sailed as Sailing Master

aboard the Soviet Unionís first, and by happenstance last,

Whitbread entry, Fazisi. With more than 200,000 miles of offshore

sailing to his credit Brian is uniquely qualified to write about

sails and the business of making sails.

Brian also owned

his own boat, Great Circle an Open 50 carbon-fiber,

water-ballasted sailboat designed and built for single-handed

sailing and Brian did a number of solo offshore passages. Some of

his experiences are recounted in his book, The Risk in Being

Alive, published by Nomad Press. These days he works on special

sailing projects and writes for magazines around the world while

raising a family in Marblehead, Massachusetts.

|