Custom Boatbuilders Use

Boat-Mounted Mooring System

Custom boatbuilders use the very finest techniques and materials when creating luxury craft for their clients. From marble floors to the thousands of hours it can take to perfect the exterior finish, this attention to detail is what makes these craft unique.

Several boatbuilders install the Boat Mounted Mooring Whip System from Mooring Products International on their custom-built craft. Names such as Abeking & Rasmussen, Broward Marine, Burger Boat Company, Hakvoort Shipyards and Skipperliner Industries use this system for towing tenders on the craft they design and produce.

|

Mooring Products is the creator of the original Mooring Whip system. Introduced in 1956, the system was perfected in the demanding mooring conditions of Fort Lauderdale, Florida. This area is subject to tides, severe storms and winds and heavy boat traffic.

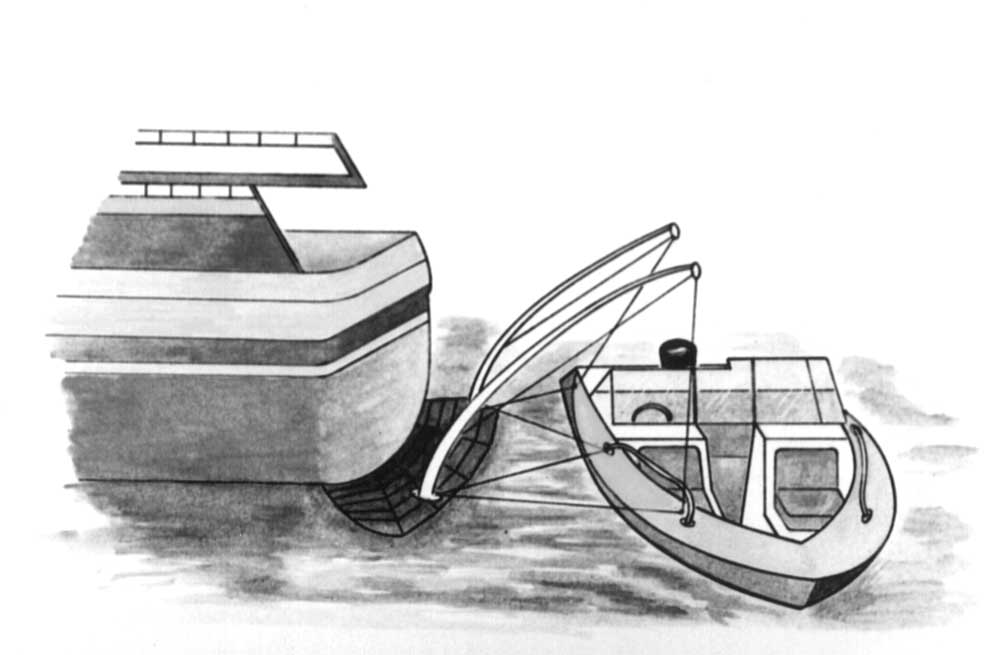

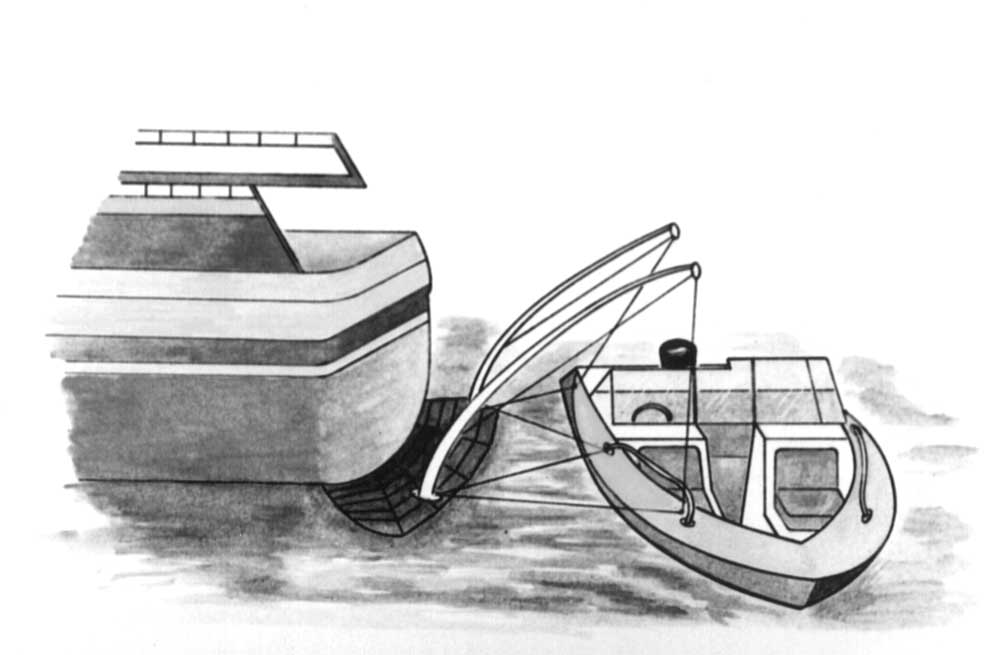

The Boat Mounted Mooring Whip System is a proven means of preventing damage to the boat. It works by maintaining a safety zone between the tender and the craft.

The system consists of whips, which are specially designed solid rods with a roller at the tip. The rods are placed in flush-mounted chrome or stainless bases mounted on the swim platform of the larger craft. A line running through the whip to the tender puts tension on each whip. This creates the safety zone between the tender and the boat. When the line tension is released, the roller acts like a pulley for easy retrieval of the tender.

The Boat Mounted Mooring Whip System includes two marine-grade bases, two solid fiberglass whips with roller tips, two whip cleats for line adjustment, all necessary hardware and lines and complete installation instructions.

Various Boat Mounted Mooring Whip System models secure craft up to 1,000 lbs., 5,000 lbs. and 10,000 lbs. Retail prices start at $409. From Mooring Products International Inc., 1189 N. U.S. Highway #1, Ormond Beach, FL 32174.