|

Steele’n

TIME

Restoration of Fire-Damaged

Beneteau Oceanis 390 in

Sault Ste. Marie, Ontario

By David Steele

During my time on the Internet I was able to track

down the original owner of the boat through the boat

title records in Ohio. I discovered that a person in

North Carolina originally owned the boat before it

was brought to Ohio. Amazingly I was able to track

down the original owner’s address and telephone

number in a matter of minutes. I eventually spoke

with the original owner to gain additional info on

the boats history. I was able to gain valuable

information regarding the condition of the motor and

amount of use the boat had seen in the past. He

explained that the boat had only been used for about

3 years before being struck by lightning at his dock

in 1999 and that this was the cause of the fire, not

vandalism as the seller had told me. This lack of

use explained why the hull was in such good

condition but also gave me particular concern

because now I was also looking at possibly replacing

many if not all of the electrical components and

wiring, something that could and would add

considerable time and cost.

|

We had made arrangements to have

the boat delivered to a nearby marina located about

2 miles from our home called Gitchee Gummee Marina

in Havilland Bay. When the boat finally arrived in

mid August the first order of business was to

enclose it with some sort of temporary structure to

prevent any further water damage, this would also

serve as indoor storage because in Canada it seems

like winter can start anytime after Labour Day. An

old steel greenhouse frame was used to cover the

entire vessel from bow to stern. This was then

covered by an 60 x 40 tarp. The inside of the

structure was illuminated with construction lights

powered by a generator while we were working.

After enclosing the boat from the weather we had

more time to survey the damage and remove parts that

were too badly damaged to be repaired, which turned

out to be most of them. A “To Do” list was prepared

that would include items that had to be repaired or

replaced in order to restore the boat to minimum

operating condition, a second “Wish List” was

prepared to which would be the items we would like

to have on the boat in order to make it more

comfortable cruising on when complete, these were

also the items that could be easily deleted if costs

began to become prohibitive. After reviewing the

lists we estimated an amount of time that it would

take to complete each one, this was probably our

first mistake as we learned later that everything on

a boat takes twice as long to repair and costs twice

as much. Perhaps we were forgetting something but

when we added the numbers up it looked like it was

possible to have the boat easily completed in about

8 months working part time at it. Could this be

possible?? Shouldn’t be a problem, I built my house

in 9 months. Once again an adrenaline rush over took

me and I started telling some friends that I might

have this boat in the water by next spring. This

might have been my second mistake because I think

they all realized how much work was involved and

knew they would have to help in order to make this

new deadline. Discussing this new time frame with

the wife was another story. I thought this was

supposed to be a five year project? Why do we need

to get it completed so fast? When will you find the

time? And how do you plan on paying for it? These

were a few of the questions she asked, some of the

others cannot be printed! With surprisingly little

convincing she agreed that we would put most things

on hold and try to complete the boat for next

spring, I was starting to see that she was just as

excited about this as I was.

We only had about 2 months to

complete the work required to seal the boat from the

elements and do any work that was temperature

sensitive as winter was quickly approaching. During

this period my daily routine was to generally come

home from my regular job and start another 8 hour

shift inside some cramped area within the boat,

weekends would involve many 16 hour days. Loretta

and the kids would bring supper over to me and would

usually try and clean some additional areas of the

boat as the smoke had penetrated every nook and

cranny, it was their way of saying I miss you! Over

time the boat even started to feel like home, it is

truly amazing that when you are immersed in a

project like this that you become totally enveloped

by it, you actually become addicted to it; truly

eat, sleep and breathing it. We are not sure if this

was good, bad, or normal.

|

During this time we were able to

basically remove the complete interior of the boat

and reinstalled only the pieces that were not

damaged, millwork that was to be repaired or

replaced was taken to my heated garage where I have

a fairly decent array of woodworking tools. Keel

bolts were replaced, headliners changed, deck and

interior fiberglass refinished, hatches resealed,

etc, etc... Measurements were also taken of any

required sailing or mechanical/electrical part that

would be needed by the spring. An electrician friend

of mine also spent six days with me “ringing” every

wire on the boat to confirm that they were OK after

the lightning strike. Interestingly enough we

actually found the circuit that caused the fire. We

also determined that we needed a complete new main

electrical panel as well as a voltage regulator and

an alternator.

Work at the boat pretty much

stopped by mid November due to the cold. Heaters

placed inside the boat could not adequately bring

the boat up to a comfortable temperature not to

mention it was very difficult to work in winter

clothing and gloves. Everything at the boat would

now have to wait until April but there was still

plenty to do in my work shop at home.

During the winter I continued my

“the second shift” basically dividing the time

between working in the garage and surfing the

internet. Parts required to be tracked down and

ordered were items like special order ash plywood to

match the existing interior, electrical panel,

winches, traveller, pedestal, quadrant, engine

parts, lighting and even door handles. These were

the items from the “To Do” list but the items from

the “Wish List” were also just as numerous. When the

decision was made to speed up the restoration we

also made the decision to do it the way we would

like the first time with all the bells and whistles.

We decided to install top of the line marine

electronics which included a Raymarine C120 chart

plotter, radar, sonar, wind, speed, depth gauges and

autopilot. In addition for comfort we also planned

on installing a new VHF radio, DVD/MP3 player as

well as three 15" LCD TVs with surround sound (one

in each cabin and main salon). In order to power all

this electrical equipment we would also purchase two

150 watt 24 volt solar panels capable of providing

up to a combined 26 amps of power with a special

Blue Sky controller. All this would be mounted on a

new stainless steel radar arch complete with davits

to carry the zodiac nice and high. Purchasing all

this equipment in time meant spending as much time

on the computer as working in the shop. I am not

sure how long it would have taken to do this type of

research ten years ago without the internet, even

with a low speed dial up connection the task was

made much simpler. Using the internet also makes the

world a much smaller place as we were easily in

touch with experts and companies all over the world

such as France, Italy, England and of course the

USA.

That winter we did not receive

as much snow as usual, this was a blessing, coupled

with unusually warm weather at the end of March

enabled work to begin back on the boat by April 1st

which gave me about 7 weeks to have the boat ready

for launch in mid May. Once again the “second shift”

began.

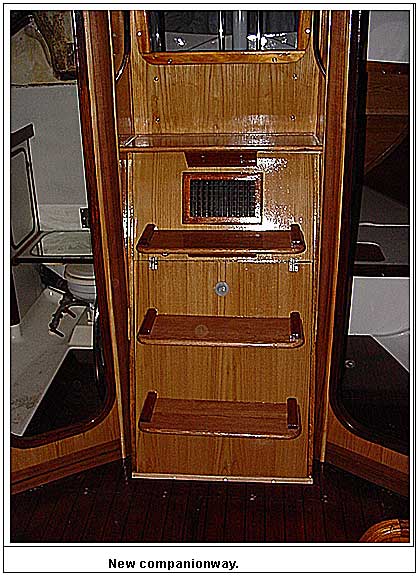

Installation of the completed

new and refinished millwork began first, at the same

time new wires and cables for the new electronics

were also installed as it is much easier when

everything is removed, heaven forbid I ever have to

re feed anything! In addition to the existing wiring

we eventually installed approx 1500 feet of

additional new wiring to service all of these new

components. Final touch ups of the interior were

completed and when the weather became warm enough

the entire interior received 3 more coats of spar

varnish everything once again looked like new with a

mirror finish when completed. All final electrical

connections were also completed at the new panel as

the new electronics were being installed and

commissioning of them began.

|

Now it was onto the motor which

hadn’t been run since the fire in 1999. After a few

feeble attempts to test and start the Volvo Diesel,

one which resulted in a snapped off starter gear

which in turn fell down into the motor behind the

flywheel. We then had to remove the transmission,

bell housing and flywheel in order to retrieve all

the bits and pieces of the gear. Now I know why they

say never hook up a garden hose to your fresh water

intake! The motor had flooded with water causing a

hydraulic lock in the cylinders, when we turned the

motor over the cylinders were full of water and

something had to give, thankfully it was just the

starter as it could have been much worse. You would

think that after doing all this work on the boat

that I should have realized my limitations long

before now and called a mechanic in the first place.

I was beginning to wonder if I had left the motor

too long and that this hunk of steel could be my

downfall. What if I ruined the engine? I would never

be able to buy one and install it before the

proposed launch or even afford it. I was finally

starting to get discouraged, I told my wife that if

the motor was finished so was I for this year. Was I

starting to fall into the same trap as the previous

owner and ready to give up so easily? I contacted a

friend of mine who knew a very good diesel mechanic

although he had never worked on a boat before he was

up for the challenge. The mechanic was out the next

day and after spending about 15 hrs on the metal

beast it came to life and began to roar! This time

the intake water was being sucked out of a bucket!

He reported that I had caused no damage with the

water but said that I should be glad that the motor

locked up as apparently the turbocharger was seized

and if it had started would have caused major damage

to the motor. With this news I was back on schedule

for mid May launch.

With only the radar arch and

solar panels left to install I would even have time

to paint the bottom of the boat prior to launch. Its

weird but this may be the only time in my life that

I actually looked forward to painting the bottom of

a boat but based on what I had completed in the last

6 months it seemed rather minuscule.

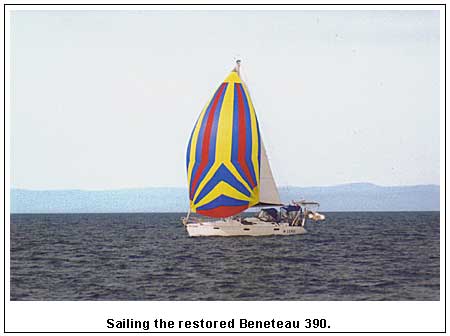

The boat was officially

completed three days before the scheduled launch

date of May 19, 2006 which was almost a year to the

day from the first time I had laid eyes on her on

EBay. On launch day I had several friends, family

and fellow sailors attend to watch this major

milestone and join in on the celebration, I also

think that some of them were there just to see if it

would float. Well it did float and it even looked

better in the water, that day the boat was also

christened with its new name “Steele’n TIME”,

partially based on our last name and what had to be

done in order to accomplish this project so fast.

Once rigged we spent the next few weeks conducting

shake down cruises around the bay in order to get

all the gremlins worked out. Once fully operational,

confidence in the boat grew quickly and we

eventually sailed over 1200 miles that first summer.

The following summer of 2007 we would go onto

sailing over 2200 miles on the boat, our motto has

become “let’s steal some time”.

Looking back in retrospect I do

not know if I would attempt a project of this size

again, quite frankly I am not sure if I would have

the energy or sanity to do it all over again the way

I did; patience or lack of it is truly a virtue.

Perhaps if I would have kept with the original time

frame of five years for completion the boat may have

never been completed as I am sure it would have

become more of a burden on the rest of my life and I

would have more than likely given up on it. In

addition to the energy required if it were not for a

supportive family and particularly my wife Loretta

assisting whenever she could it would not have been

possible in the first place. She also really enjoys

sailing the Great Lakes and truly shares the dream

of sailing away someday. When we look back at photos

of the condition of the boat when we first purchased

it we often think that we must have been crazy or

blind. We have never added up all the costs, this

alone would probably be another good reason never to

attempt again. We have also never added up all of

our man hours working on the boat however I do know

that there were so many that I did wear out a gas

powered generator while working on the boat so there

must be more than a few. On the positive side I know

my boat inside and out which is a definite

requirement for any Captain. I have also become much

more knowledgeable with regards to boat repair and

all systems on a boat; it seems that I have become

somewhat of a local expert, kind of a Nigel Calder

of the North (with the exception of diesel engine

repair). Even though my project is now complete my

work seems to never stop because recently two

friends of mine have bought boats that would

classify as fixer uppers. Although they are not even

close to the extremely poor condition that mine

started out in they will still require a fair amount

of work to complete, and I have a lot of favours to

repay.

|

Ask me if I would do it again?

“Maybe?? Given the chance, but I don’t have to

because I already have the boat of my dreams, it’s a

Beneteau called Steele’n TIME”.

This is the conclusion to the article from the

April 2008 issue.

Dave Steele has been avidly

sailing the Great Lakes for over twenty years,

logging over 18,000 miles in his travels. From their

home located at Harmony Beach, Ontario, Dave along

with

his wife Margaret (a.k.a. Loretta) and their two

daughters Morgan and Mikayla spend as much time as

they can exploring the remote northern shore

of Lake Superior and Lake Huron’s North channel.

TOP

|