Scows

have been racing the inland lakes of America for over 100 years.

For nearly that entire time A-Scows have ruled the waves as the

premier class of inland lake racing. In the alphabet soup of Scow

racing, Cís, Xís, Mís, and Eís all have their attributes, but the

A-Scow has always reigned as the place where the big boys take

their big toys and put their big egos on the line. Scows

have been racing the inland lakes of America for over 100 years.

For nearly that entire time A-Scows have ruled the waves as the

premier class of inland lake racing. In the alphabet soup of Scow

racing, Cís, Xís, Mís, and Eís all have their attributes, but the

A-Scow has always reigned as the place where the big boys take

their big toys and put their big egos on the line. At 38 feet the A-Scows are the largest and fastest of the scows. Itís not unheard of for Aís to hit speeds of 25 knots. Historically, the fleet has been considered a ďdevelopment classĒ with a ďbox ruleĒ that allows any design that stays within certain parameters. During the last decade, however, the fleet began to depend on a single boat builder and began to lose some of itís reputation for being a fleet that encourages and rewards innovation. Last year, long time Lake Minnetonka scow sailor, Brad Robinson built a new class legal A-Scow thatís been making waves in scow racing since itís debut. The boat is not radically different from current A-Scows, but it demonstrates what you can accomplish with a clean sheet of paper. Designing the Next Generation Scow: In 1995, seeing the drawbacks of a design that was decades old, Brad began the process of evaluating the current boat designs and considering designs that would re-invigorate the A-Scow fleet. Along with his own ideas about rigging and deck layout, he enlisted the help of several east coast designers with ties to Americaís Cup design programs. One of the original designs included a radical carbon fiber hull that would weigh a scant 1200 lbs. for a 38í boat. But these designs did not conform to the existing rules and were radical enough to immediately outdate the entire fleet.  In

2001 a builder was found who could make molds and a hull for the

boat. This is no small task, and the fact that PAR Systems in

Shoreview, Minnesota was a local company made it too good of an

opportunity to pass up. A conservative hull shape (based on the

existing hull shape most racers currently used) was chosen and

the building of the hull commenced in December of 2002. In

2001 a builder was found who could make molds and a hull for the

boat. This is no small task, and the fact that PAR Systems in

Shoreview, Minnesota was a local company made it too good of an

opportunity to pass up. A conservative hull shape (based on the

existing hull shape most racers currently used) was chosen and

the building of the hull commenced in December of 2002.Robinson choice of a conservative hull shape was part of his long-term plan to donate the hull tooling to the Inland Lake Yachting Association (ILYA) A-Scow fleet. With this, the fleet could own a hull shape for their fleet and be able license itís use to suitable boat builders. These licensing fees could be used, in turn, to fund fleet promotion. Furthermore, most A-Scow owners have wanted to see the fleet rules tightened up to make the fleet closer to a ďone designĒ fleet, and this would be one way of accomplishing that goal. In 2000, preliminary design research had included taking an existing Melges A-Scow and measuring the hull with a laser inferometer. This created precise digital drawings of the hull that included all the bumps and non-symmetric idiosyncrasies of the hull. The basic shape for the new hull was decided to be the same as other A-Scows. The only noticeable difference is approximately 6cm of additional hull width at the bow and stern of the boat. While this increases drag in light air, it slightly increases waterline length up to the point when the boat starts to plane in moderate to heavy winds. Itís a trade-off that avoids potential copyright infringement of another boat builderís design while insuring that the fleet can move toward tighter design rules. The Building Process: The first step was to build a plug for the hull molds at PAR Systems in Shoreview, minnesota MN. They operate a huge computer driven five-axis milling machine that was able to precisely create a rigid Styrofoam plug. While this Styrofoam differs from the stuff you might find in your beer cooler, itís ideal for a large plug because itís light enough to operate in the milling machine, itís easy to cut, and itís shape is very stable. These resulting plugs provide exact copies of the intended hull and deck shapes with which to create molds. Not all molds are made this way. Some molds are called ďsplash moldsĒ because they use an existing boat has a hull plug. While this method saves money, it also reproduces any waves, twists, or manufacturing errors from the original hull. Molds are next created for the hull and deck using the plugs. These are made of heavy fiberglass and can be used over and over again. To keep the molds in their proper shape, heavy steel frame are built around them for reinforcement and support. To create the actual boat hull and deck, the materials are layered within the mold from the outside moving in. The deck is eventually attached to the hull, and then both hull and deck are lifted out of the hull mold. From this point on, itís a matter of drilling holes, mounting hardware, and painting a name on the side of the boat. Details Make The Difference: The real differences with Robinsonís new boat are the accumulated benefit of many small changes to the rigging of the boat. Heís been racing and tinkering with scows his entire life and this was Robinsonís chance to start from the ground up with his own ideas. So letís take a tour and see some of tweaks that prompted Robinson to name his new boat The Victory.  Bow

sprits and asymmetrical spinnakers were introduced to A-Scows

about ten years ago and are now filtering into other scow

designs. But there are problems with this because the low profile

of scow hulls place the foot of the spinnaker so close to the

water that itís difficult to see other boats. This is a big

distraction when youíre sailing at 20 kts. Bow

sprits and asymmetrical spinnakers were introduced to A-Scows

about ten years ago and are now filtering into other scow

designs. But there are problems with this because the low profile

of scow hulls place the foot of the spinnaker so close to the

water that itís difficult to see other boats. This is a big

distraction when youíre sailing at 20 kts. Robinsonís solution was to point the bow sprit skyward placing the spinnaker tack over four feet above the water. On an A-Scow, itís a stomach-crunching crew that replaces the keelís job of keeping the boat upright. While Robinson couldnít eliminate the work of holding your head out of the water, he was able to slightly round the edge of the deck and make the whole ordeal more comfortable for everyoneís backside. Because of their width, A-Scows have two rudders. A single rudder in the center of the hull would often be out of the water when the hull heels over. Robinson moved his twin rudders further outboard, which improves maneuverability. On an earlier A-Scow, Robinson had begun using foil shaped rudders, which were a significant improvement over the previously flat and shapeless rudders of a by-gone era. Robinson was the first to use foil rudders back in the mid 90ís.  On the back of any scow with twin rudders, youíll notice connected twin tillers with the leeward tiller not in use. Victory eliminated this mess with a commonly found single tiller on the deck that uses below deck tie-rods for controlling the two rudders. The jib on Victory is self-tacking. A curved track on the foredeck allows the sheet to auto-tack from side to side with one line lead to the cockpit that controls the tension on the sheet. Thereís no pulling an armful of jib sheet during a tack, you simply trim to account for acceleration out of the tack. The single track means that you canít adjust the angle of the sheet like most of us do with our typical jib layouts. For Victory, the jib sheet attaches to a clew that allows for different attachment points. Attach it low to add sail twist, attach it high to allow depth in the sail. A future design of this sail will incorporate an adjustable lead on the clew board so the lead can be adjusted while sailing. A-Scows have several different variations of boom vangs. Most noticeably, the vang on Victory doesnít lead from the boom to the base of the mast. Instead it leads straight down to a track that runs across the deck similar to the mainsheet track. On most sailboats, you tighten the vang to force the boom to bend the mast, which flattens and de-powers the mainsail. On an A-Scow, you use the backstay and running backs to control mast bend while the vang is mostly for keeping the boom low while sailing downwind. The end result of Robinsonís numerous tweaks has been a boat thatís easier to sail and manage around the racecourse. The biggest challenge of sailing an A-Scow has always been to simply keep the boat from breaking or tipping over, so any improvement in ease of handling allows the crew to focus less on mechanics and more on winning races.  An

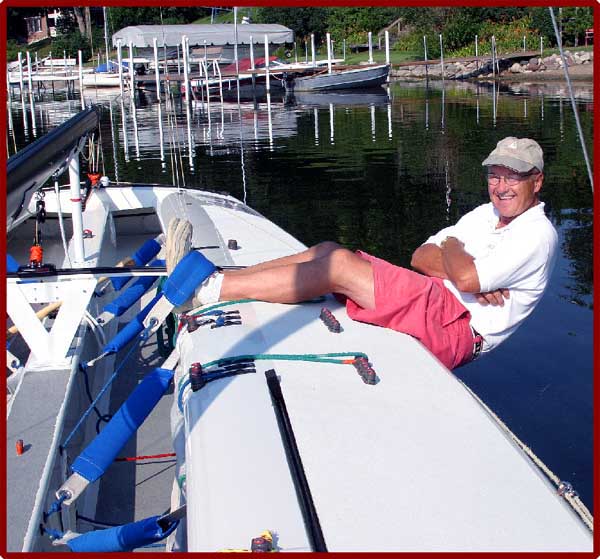

easier boat to sail also helps keep sailors competitive later in

their careers. The Victory crewís average age is 50+. They are

all in good shape, but these guys arenít muscling the boat around

the course. An

easier boat to sail also helps keep sailors competitive later in

their careers. The Victory crewís average age is 50+. They are

all in good shape, but these guys arenít muscling the boat around

the course. On The Water: Of course the boat is only part of the equation when it comes to racing. Robinson has recruited experienced sailors whoíve owned and raced A-Scows for decades. They were successful with their previous A-Scow program and managed to win an impressive 12 of 21 major regattas they competed in. In their first year of competition with the new hull the Victory program has seen some success on the racecourse. In their first season, they finished second in the A-Scow Inland Championship on a tiebreaker, and managed a win at the ILYA Invitational. While the Victory didnít win many individual races at major regattas, they consistently finished in the top three and rarely had a bad race. This indicates a boat that might not have dominant boat speed, but a boat that allows to crew to sail well, keep their head out of the boat, and not make mechanical or tactical mistakes on the racecourse. The very idea of a newly designed A-Scow has been intimidating to some sailors, so Robinson elected to forgo receiving trophies at the regattas he entered in his first season. But for 2004 the racing will be for real. Scandal in Scow Country: Anytime someone succeeds at something new in racing, youíre going to end up with both fans and critics. Robinson has no shortage of either. Thereís a general trend in the A-Scow fleet to tighten up the rules and limit the potentially expensive development of new boat designs. Even though the cost of building Victory was comparable to a factory-produced boat, itís a difficult and intimidating process for even A-Scow owners to undertake.  Within

the past year, the ILYA A-Scow class has refined their rules to

restrict any new boats with modified hull shapes; this includes

the Victory hull, which will be ďgrandfatheredĒ under the new

rules. Most measures consider the hull shape differences to be

inconsequential. But this clause has caused enough controversy

that some owners have moved to form a new racing organization

that bypasses the century old ILYA. Within

the past year, the ILYA A-Scow class has refined their rules to

restrict any new boats with modified hull shapes; this includes

the Victory hull, which will be ďgrandfatheredĒ under the new

rules. Most measures consider the hull shape differences to be

inconsequential. But this clause has caused enough controversy

that some owners have moved to form a new racing organization

that bypasses the century old ILYA. The newly formed National Class A Scow Association (NCASA) is closely affiliated with Melges Boat Works, the dominant manufacture in the class. Like the updated ILYA rules, their class rules are also significantly tighter than the old ILYA A-Scow rules. For Victory, the most important difference is that they effectively outlaw the Victory from competing against Melges boats. The class is currently in a struggle to decide itís future and the Victory has become central in that struggle. On one hand, the fleet can attempt to make their fleet a strict one-design rule thatís designed around the Melges boat, and that boat only. The other option is to stick with the newly tightened ILYA rules that are similar to the new national class rules except that they are overseen by the ILYA. Regattas for the NCASA have been scheduled for the same dates as traditional ILYA regattas in 2004 in direct competition with those races. What will come of all this remains to be seen. Many of the current Melges boat owners have been willing to band together. For many of them, itís about preserving the resale value of their boats.  But

the ILYA A-Scow sailors have no intention of just drifting away

to allow the national class to take over its operations. Many

people view the Robinson boat as central to the spirit of scow

racing. Itís new, itís fast, itís well designed, and itís a

natural evolution of the fastest, most advanced, and fun design

around. But

the ILYA A-Scow sailors have no intention of just drifting away

to allow the national class to take over its operations. Many

people view the Robinson boat as central to the spirit of scow

racing. Itís new, itís fast, itís well designed, and itís a

natural evolution of the fastest, most advanced, and fun design

around. Thereís a long and successful tradition of the A-Scow fleet thatís survived many challenges over itís 100 year history, and itís often been a bellwether of the future for other scow classes. Although this is a chapter thatís still being written, we already know itís one that will be remembered for years to come. Itís going to be an interesting summer in Scow Country. Robinson has created a web site that goes into great detail with photos regarding all these features of the boat and the process of building the boat. Check it out at www.VictoryByDesign.org. |